There are many different types of fabric printing methods, and they all yield different results. The type of textile printing used is often based on a number of considerations, from print runs, to durability. We have pulled together some of the most popular, or most commonly used methods, and explained them below.

Fabric Printing Methods

1. Stamp Printing

This one is pretty much what it says it is. A stamp is created, and that is then used to imprint onto the fabric. Similar to making potato stamps when you were a child, to create beautiful paintings. Your design is cut into the stamp, which is then dipped into the ink and using even pressure, you transfer this from the stamp onto your textile. Although we’ve come a long way from potato stamping, the level of detail that you can get from stamp printing is limited, so this is not suitable for the more intricate designs.

Pros

- No need for machines

- Design is always exact

- Great for small runs

- Cost effective

Cons

- Not very detailed

- Can’t make large quantities

- Only one design per stamp

- Quality is inconsistent

2. Transfer Printing

Another method is using transfer paper. This is a specialist paper which can be bought from most stationers, as well as craft shops and even some supermarkets. You can use a standard household printer to print your design onto the transfer paper, which you can then print onto your chosen fabric by using a standard, household steam iron. This can be upscaled and done professionally on larger runs however it will leave a shiny film or surface texture on your fabric. It is not a permanent method of fabric printing as it can crack and peel with multiple washes, and often fades.

Pros

- Can print with standard printer

- No specialist equipment needed

- Great for small runs

- Easy to print and transfer

Cons

- Leaves a surface texture/film

- Transfers are single use

- Peels, cracks and fades

- Can suffer from low resolutions

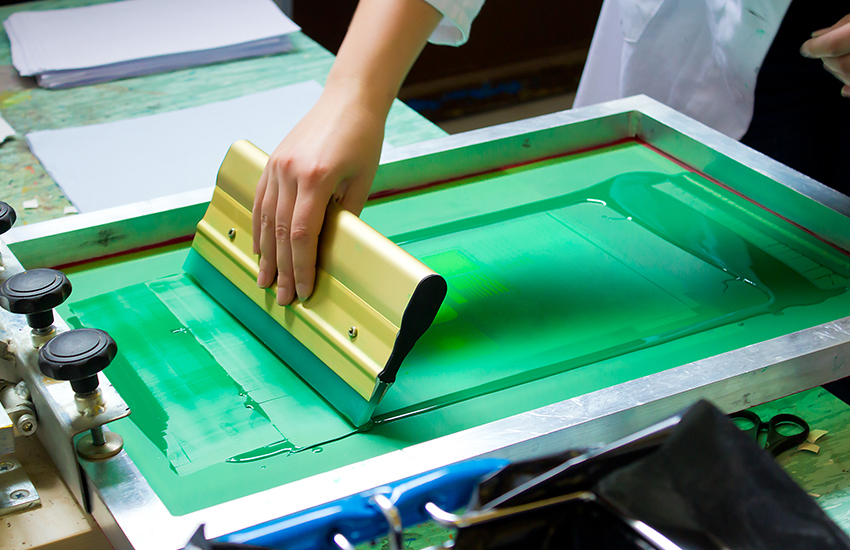

3. Screen Printing

As we move towards the other end of the scale, we start to see methods which are used more and more commonly within the professional world of textile printing. Silkscreen printing is most common within the business. This method of printing uses a stencil and a nylon mesh to create the print design. A material which is waterproof will be used to block out the spaces that you want your design to appear on, and then those blocked out spaces are flooded with ink. Due to the way that this method is carried out, you can only use one colour for each screen, however, it does produce fantastic replications.

Pros

- Amazing image reproductions

- Long lasting

- Ideal for sharp edges and solid blocks of colour

- Cost effective for large runs

Cons

- One colour per screen – not ideal for multi-coloured designs

- Very labour intensive, impractical for small runs

- Not great for photos/graduating colours

- Creates a lot of waste

4. Dye Sublimation

This is a multi-step process which produces some of the best results of all the fabric printing methods. Designs are printed onto a thermal transfer paper, known as dye sublimation paper. This is then used to create the print on the fabric. Both heat and pressure are used to permanently bond the inks to the fibres of the fabric. This leaves your fabric as soft as it was before it was printed on. The deep infusion technique penetrates specialist water-based inks deep into the textile, which makes your print permanent. Perfect for intricate details as well as colours.

Pros

- Amazing image reproduction that is permanent

- Leaves no texture or residue on the fabric at all

- Eco-friendly, water based inks dont fade or peel

- Suitable for all size print runs

Cons

- Not for use on natural fabrics, only on poly textiles

- Requires specialist equipment and dyes

- More expensive printing method

- Requires in-depth knowledge and experience

5. Pigment Printing

Pigment printing is one of the most popular printing techniques for use on cellulose fibres, making them ideal for use on natural fabrics. It is one of the fabric printing methods which can be used on synthetic materials as well, which makes it pretty versatile. It is a localised technique which involves applying the dyes to the part of the fabric that you want your design to be seen. This is done over and over and slowly builds up the colour.

Pros

- Bright printing with permanent colour

- Easy to do, good colour matching

- Cost effective, no high end machinery

- High-speed printing technique

Cons

- Not applied directly to the fabric

- Uses binders whcih leave a coating on the textile

- Colour lessens when repeatedly used over the same material

- Dye sits on top of the fibres rather than embeds

6. Reactive Printing

Reactive printing is another of the heat activated fabric printing methods. It is done by pre-coating the fabrics and then and using a binder (similar to that of pigment printing) and a printing additive. It prints a dye or wax onto the fabric, and the heat reaction permanently bonds the image to the textile. Put simply, it is similar to coating the fabric with the design and then steaming it to create a reaction which bonds the design to the material.

Pros

- Creates a chemical bond between the ink and fabric fibres

- Works amazingly well on natural textiles

- Wash-fast and rub-fast

- Outstanding colour vibrancy

Cons

- Requires pre-treatment

- Also requires post-treatment

- Not particularly easy to carry out

- Not the most cost-effective printing method

Try your own fabric printing online – it’s so much easier than you think.

Great article! I am a Materials, design and technology teacher and will definitely be sharing and demonstrating a few of these techniques with my students as they are in the process Of investigating surface design and we have already been playing around with Suminagashi dyeing with great results.

Thanks for sharing

Carolyn

Hi,

I would like to know which technique is best to use for digital printing on curtains .

Thanks

Gurmeet

A very busy family member has produced very imaginative and original art work which would, I’m sure look very good on textiles. I’m researching for him.

Free formaldehyde discharge print feel not good, equal non PVC,

Cracking , thicker print,

So any solution.